It’s difficult to get away from vibration in shipping. Nearly every means of conveyance vibrates at some frequency — truck, plane and train engines vibrate especially perniciously — and that vibration can be destructive to packages and shipped items. But why? How can such a small, subtle movement destroy so much freight?

Interestingly enough, the answer lies in the physics of sound. If you want to stop your packages from vibrating to pieces, read on to learn about the science of mechanical resonance.

How Mechanical Resonance Works

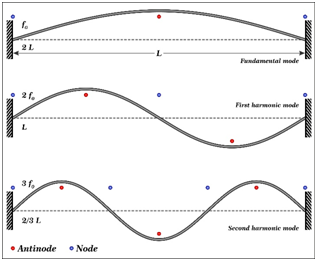

Sound is nothing more or less than vibration.Sound starts with the vibration of some material, like the top of a snare drum, and continues through the airinto your ear. Sound can cause other materials to vibrate as well —imagine placing a glass of water next to a subwoofer; you’d likely see ripples in the water, which prove that sound waves are passing through. Sometimes, sound can be amplified by the materials it passes through because those materials vibrate at the same or greater intensity than the air surrounding them. This is called resonance, and a good example of it is when singers break glass using only their voice.

Mechanical resonance is when a mechanical system, like an engine in a shipping truck, shares a resonance with items surrounding it. Often, when an item comes into contact with its resonant frequency, it gets shaken apart — like the glass shattered by singers. Any material can be susceptible to damage via resonant vibrations; it’s just a matter of finding the right frequency to do so.

This phenomenon is undeniably interesting. In fact, mechanical resonance is to thank for many important processes relied on by humans, like the quartz crystal within clocks or the orbital resonance of moons. However, it is also typically bad for everyone involved in shipping, from shipping companies themselves (who must often service their vehicles to combat mechanical resonance) to those tasked with infrastructure repairs (because roads and bridges often suffer from mechanical resonance) and especially to businesses looking to ship goods (which often sustain damage due to vibrations). It should hardly be surprising that most shippers around the world are constantly on the lookout for new ways to detect and eliminate mechanical resonance during the shipping process.

How to Stop Mechanical Resonance from Causing Damage

It’s important to note straightaway that it is impossible to eliminate vibration from a large and complex mechanical system like an engine. Still, it is possible to reduce the intensity of those vibrations and protect cargo in other ways. For instance, shippers can invest in fleet vehicles that contain innovative, vibration-reducing construction, like these:

- Flexible engine mounts. By allowing the mount to move with the shaking engine, the mount will absorb and dampen many of the most intense vibrations, preventing them from resonating with the rest of the vehicle.

- Stiff vehicle body. A structurally rigid vehicle frame resists the vibrations of the engines, which helps reduce their impact.

- Harmonic balancing.Also called a vibration damper or a crankshaft pully, this rubber or fluid-filled device dampens the forces imparted on the crankshaft to prevent transmission of vibrations down the vehicle.

- Active vibration control. Functioning like noise-cancelling headphones, active vibration control systems listen for vibrations and produce counteractive frequencies. These systems can be installed in any vehicle, but they can also be quite costly.

In addition to choosing shipping services that make vibration control a priority, businesses shipping goods can alter how they package their goods to prevent unwanted resonance. With the help of vibration monitoring tools, which identify what vibrations occur during shipping and what could potentially harm shipped items, businesses can develop more absorbent and secure packaging to further dampen mechanical resonance.Stiff, dense protective liners within shipping boxes are tried-and-true ways to increase protection against vibration.

Mechanical resonance is a fascinating physical phenomenon — but one that most shippers want to avoid rather than indulge. While you shouldn’t expect to eradicate vibration or resonance, you can take steps to reduce the damage it does to surrounding materials, which helps everyone in the shipping chain feel more secure.