Does your busy still rely on manual processes? Have your automated solutions quickly grown outdated? Or perhaps you’re looking to improve the way your business operates within the industry?

There’s no denying that outdated and manual processes are time-consuming, costly, and less accurate than automated systems. For your business to cut costs, increase efficiency, and maintain accurate systems, it is essential to stay on top of the latest advances in plant and industrial automation.

Doing so is easier said than done, with a raft of new technology seemingly arriving every other day. It can be challenging to sort through the noise and find information that’s relevant to you and your business. So if you’re looking to streamline your processes while saving time and money, keep reading as we take a look at some of the most exciting developments on the horizon.

Automated Distribution

If you operate, run, or rely on distribution centers, you understand the importance of knowing exactly where your stock is at all times, the quantity you have on hand, as well as the fastest way to deliver products to your customers. It’s an effective if time-consuming process.

Automated distribution is providing a way forward by minimizing shipping errors, providing more accurate inventory quantity, and reducing the need for manual data entry. Amazon is leading the way with the recent purchase of Kiva Systems, which enabled the company to build its fleet of more than 45,000 autonomous robots that now occupy its distribution centers.

This leap into automated distribution allows Amazon to fill orders and stock shelves with little human assistance or error. While the use of robots for automated distribution and complete replacement of humans may still be a decade off, the industry is certainly moving in that direction, making this an advance to keep on your radar.

Artificial Intelligence

AI has become an essential advance in industrial automation, particularly in manufacturing and plants. AI is estimated to have a similar impact on today’s ‘4th Industrial Revolution’ as Henry Ford’s assembly line did over 100 years ago.

AI is being pushed along at a faster rate these days, thanks to the pivotal role it’s set to play in creating a sustainable future. Limited natural resources have seen the rise of AI-powered remanufacturing, which has hit the headlines recently as a viable, cost-effective, and efficient approach to sustainable manufacturing.

Weighing & Monitoring

Weighing solutions are used across multiple industries, including logistics, material handling, recycling, distribution, manufacturing, and more. It was only a matter of time before these solutions received automated treatment. Remote monitoring equipment and various load cells are now being used to improve the efficiency of processes like production lines, where they help monitor the equal distribution of packaging through autonomous container filling.

3D Printing

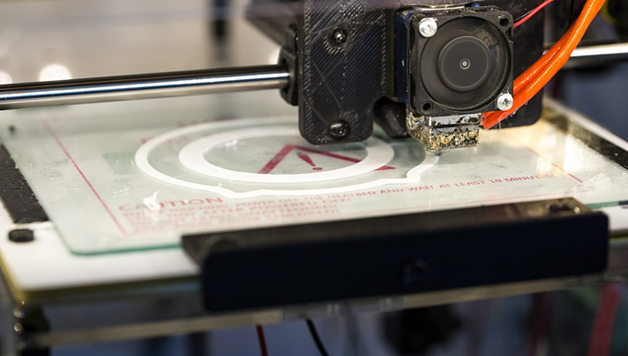

While 3D printing itself has been around a while, the technology has advanced significantly in recent years within manufacturing and automation, allowing 3D printers to produce finished parts.

With this increase in accuracy and capabilities, 3D printers are now forming a valid part of the industrial process, from 3D printing of extra parts to entirely 3D printed concrete buildings. It’s a sure sign that automated 3D printing could soon build an entire project with minimal human interaction.

Automated 3D printing is also supporting the cost-effective, customized, and efficient production of complex manufacturing. Printers are more than just a tool for hobbyists; they’re a vital component of modern manufacturing, which is why you’ll find them in end-to-end production processes across a range of industries.

Cloud Storage

Cloud storage has been one of the most significant advances in recent years, with its influence on industrial automation allowing information to be stored wirelessly and automatically uploaded anywhere, at any time, with minimal human interaction.

Automated cloud storage, for example, allows you to automate repetitive operations within plants to minimize errors and streamline systems; this has shown to be beneficial for managing data in high information environments.

The Industry 4.0 Initiative

As mentioned earlier, we are now in the 4th Industrial Revolution. Often referred to as the ‘Industry 4.0 Initiative’. This initiative is said to be as influential as Henry Ford’s domination in the automobile industry.

Industry 4.0 integrates smart networked sensors to communicate with automated systems. AI, information, and communication systems are embedded within the sensor to achieve greater efficiency across industries from field level devices to process control, and directly within value chains and planning systems.

Staying Ahead of Industry Advances? It’s Crucial

The above advances in industrial automation, especially AI, are set to play a significant role in the Industry 4.0 Initiative and the overall improvement of automation efficiency. With this new technology at your fingertips, your business will be able to boost efficiency, productivity, and profits.