Motorized machines are used in several industries around the world. For example, they are used in mills, factories, and pressing plants. Whether you facilitate a public facility or you operate a production line of mass-assembled products, many of these machines are operated 24/7.

When you think about the amount of money and time that is wasted if motors stop working, itbecomes even more obvious just how important reliable motors are. Therefore, all machines need to be built with a motor that is designed for the high-powered, high-speed jobsat hand.

For most people in the industry, servo motors are the solution. If you want to learn more about servo motors, and what the pros and cons of using them are, then keep reading below:

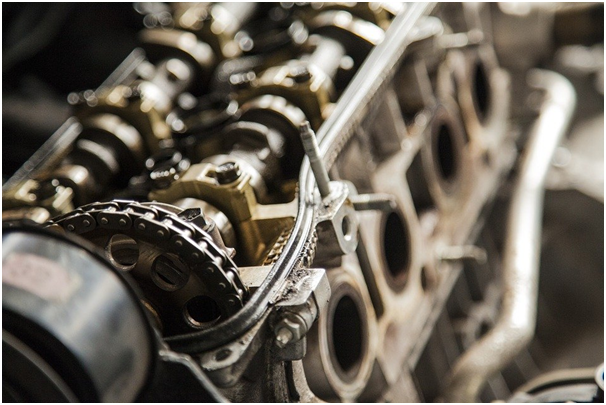

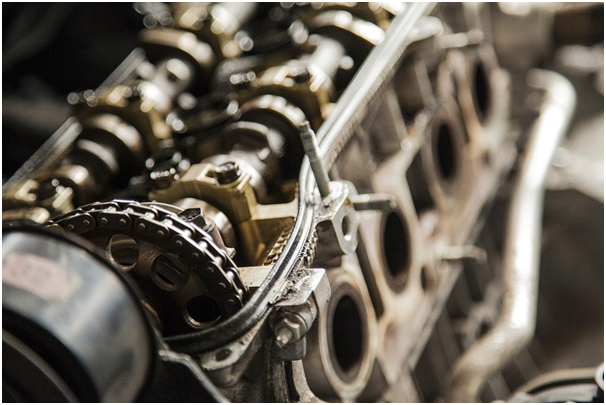

What are Servo Motors?

Motors are used in several industries around the world, but did you know that there is more than one type of motor available? And do you know the difference between a servo motor vs induction motor?

Induction motors have been an industry staple for decades. They are a low-cost solution that is perfect for a single-speed application. However, induction motors have several disadvantages. For example,they are not a universal fit. This is where servo motors come in. Not only are servo motors a better fit for most machines, but there are also several other benefits to using a servo motor.

The Advantages of Servo Motors

As we mentioned above, there are several advantages to using a servo motor. Some of the advantages include:

- They are more accurate – servo motors are the preferred choice when it comes to industrial use. This is because they are more accurate and can be easily altered to suit the application at hand.

- They are fast and flexible – servo motors are a brilliant option for people who require speed, precision, and flexibility. Unlike most other types of motors, Servomotors come with adapters.

- They have fewer drawbacks – servo motors are seen as being far superior to steppers and pneumatic actuators.Unlike servo motors, steppers and pneumatic actuators possess several drawbacks, including fixed displacement and lack of motion.

- Servo motors usually offer a better fit than other types of motors.

- The performance – servo motorscan provide the user with far superior performance capabilities.

- They are more economical – in the past, servo motors were expensive to buy however over the last few years, the cost associated with the purchase of a servo motor has decreased rapidly. While these motors are still more expensive than other types of motors, the price gap has been shrinking. This means that servo motors are now an extremely affordable option.

The Disadvantages of Servo Motors

Although there are numerous advantages to using servo motors, there are also a couple of disadvantages you need to be aware of. Some of the disadvantages include:

- They are not suitable for all applications – some applications will require a pneumatic actuator or stepper to work correctly

- They cannot be repaired easily – there are very few manufacturers around the world that have the equipment or skills needed to repair servo motors.

Whilst servo motors have several applications and use cases, across a range of industries, this does not mean that they are always the ideal choice for the job. One of the worst things you can do when choosing a motor is to choose one that is unsuitable for the job you are completing. As with any type of motor, the servo has several advantages and disadvantages. While there are more advantages associated with servo motors than disadvantages, it is still important to weigh up your decision carefully before making your choice.