Today, in every process human is interacting with machines and moreover there is an increase in human productivity with the interaction between persons and equipment.

“Human Machine Interface is a software application that presents information to an operator or user about the state of a process, and to accept and implement the operators control instructions. Typically information is displayed in a graphic format.”

Human Machine Interfaces (HMI) enables workers to perform duties with the help of concise automation equipment via an interface instead of switches and levers. As a tool for convergence of visual computing and automation control systems, industrial automation with human machine interface systems usually consist of LCD panels, often with touch screen capability, mounted on the control consoles of industrial automation equipment. In industrial automation, human machine interface systems face challenges of creating scalable HMI product families with varying performance levels, scalable graphics resolutions and different display types.

While, the industrial automation specialist argues that the internet has come into automation. It has been a long way and so the slowly growing industry is increasingly taking advantage of technologies that interpret data from systems like SCADA, supervisory Human Machine Interface, MES and EMI solutions on a single platform.

The complex the technology systems grow, the end-product equipment safety, ease of operation and risk reduction of human error are becoming extremely important. The selection and seamless integration of human machine interface components, such as switch controls, actuators and indicators, are critical to the success of equipment designed for human operation. So, doing it right provides the human touch, a desirable and friendly in modern controls.

Human Machine Interface success

Balancing at every point is very important in complex systems like human machine interface and for its success. Employing high-quality design, best practices and proven techniques result in reliable human machine interface systems, such as complete control panel inserts, that reduce end product assembly costs and extend service life. There can be engineering and financial constraints, but returns need to be in considerations while taking decision on the investments.

Another major science integration in human machine interface is industrial ergonomic. A lot of science fields and studies co-ordinate for the future development of human machine interface systems and products therefore necessitate an end-application, solutions orientated approach. Human machine interface suppliers need to work in full partnership with clients to deliver consultation and an application-engineering approach to production. Human machine interface suppliers cannot work in isolation. An important consideration in the selection of human machine interface supplier is the strength of the relationships that it has with its own suppliers, including plastics vendors, toolmakers, electrical and electronics engineers, industrial designers, and ergonomics experts.

Advancements in human machine interface

Software integration in human machine interface software solutions from Iconics are both GENESIS32 and GENESIS64 software for a variety of industries. These are 64-bit-based, multi-core, multi-processors applications that require advanced 3D Graphics and visualization, ICONICS offers GENESIS64. Taking advantage of 64-bit computing can greatly reduce engineering time, resulting in savings. GENESIS64 is the first and only HMI/SCADA software suite certified for Microsoft Windows Vista, Windows Server 2008, and compatible with Windows 7. GENESIS64 provides a complete 360 degree view of your operations in real-time.

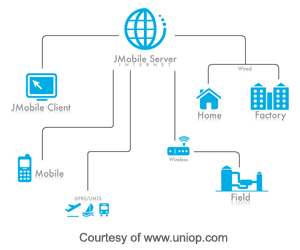

UniOP offers exclusive devices which combines state-of-the-art features and performance with an outstanding design and are ideal choice for HMI applications including factory and building automation.

Mobile Software for human machine interface integration is introduced by UniOP on the name of JMobile Software Suite. As a complete human machine interface software solution, JMobile provides remote access to equipment saving time and increasing efficiency with an Easy and Fast user interface development with client-server architecture. The suite includes commissioning tools, to allow easy maintenance and configuration of multiple remote units, and both desktop and runtime engineering software for application development.

Entrance of Brain Computer Interface into human machine interface

The interaction and co-ordination between brain and computer / machine through signals to direct an external activity is called Brain Computer Interface. All they have done is to create an alternative route for human-computer input. Whereas, brain-computer interfaces subtext is how the user learns to self-regulate brain activity in order to successfully operate this category of technology. So, the volitional control of brain activity seems like an extension of the human nervous system and one that occurs as a side effect or consequence of technology use. The brain–computer interface technology could one day replace remote controls.

Out-of-body experience is a key advantage to Hitachi’s technology is that sensors don’t have to physically enter the brain. Earlier technologies developed by U.S. companies like Neural Signals Inc. required implanting a chip under the skull. A recent study titled and describes the same.

“Multimodal human-machine interface based on a brain-computer interface and an electrooculography interface.” The non-invasive spontaneous brain computer interface registers the electrical brain activity through surface electrodes. The electrooculography interface detects the eye movements through electrodes placed on the face around the eyes. Both kind of signals are registered together and processed to obtain the mental task that the user is thinking and the eye movement performed by the user. The commands include both the mental task and the eye movements are combined in order to move a dot in a graphic user interface. Several experimental tests have been made where the users perform a trajectory to get closer to some targets. To perform the trajectory the user moves the dot in a plane with the electrooculography interface and using the brain computer interface the dot changes its height.