In today’s fiercely competitive industrial landscape, understanding and leveraging state-of-the-art technology is crucial for success.

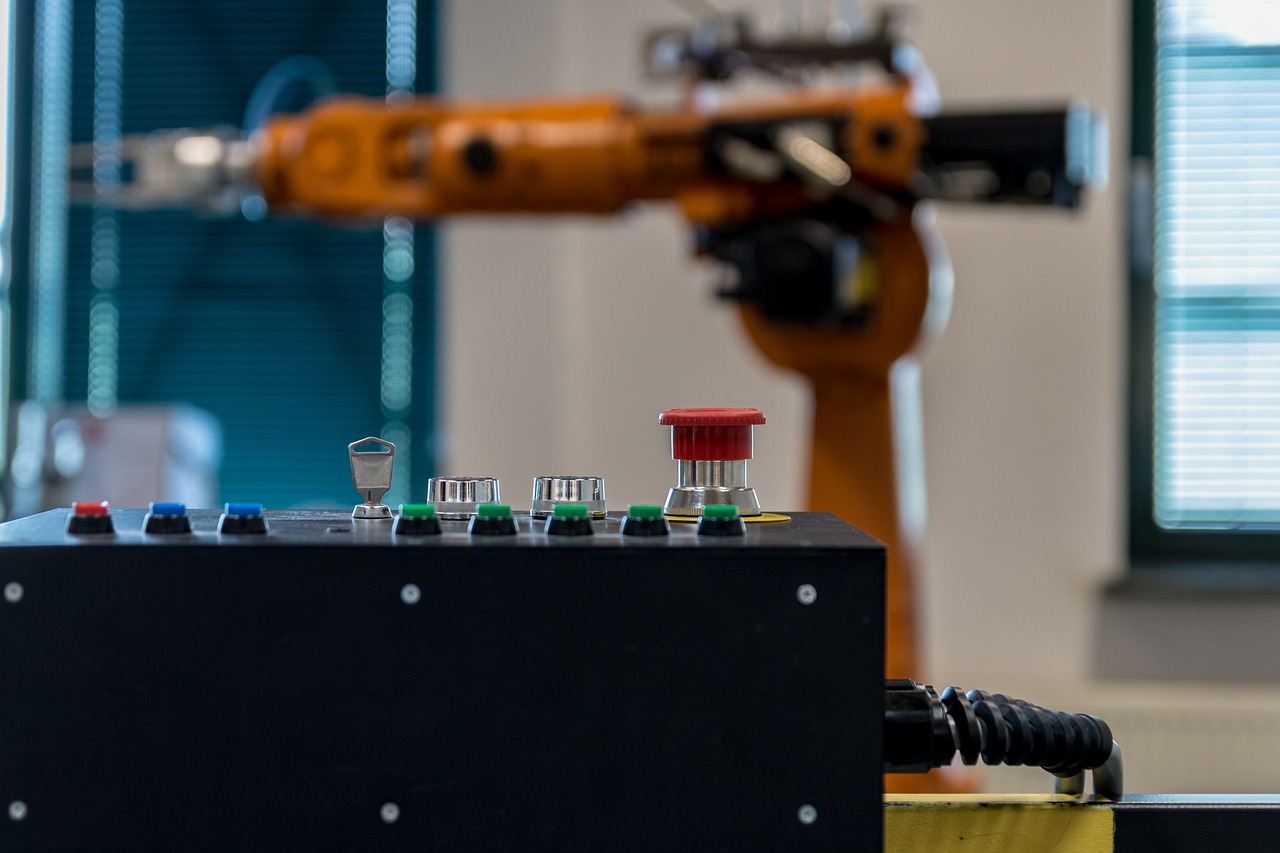

Six-axis robot arms fit this description admirably, and stand as powerhouses of efficiency which are set to redefine manufacturing processes.

To prove this, follow along as we explore how they foster industry growth while investigating real-life applications and future perspectives.

Unpacking the Power of Six Axis Robot Arm in Manufacturing

First, let’s delve into what a six-axis robot arm brings to the table. Boasting an impressive breadth of movement and flexibility, these robotic systems are akin to a highly skilled artisan who never tires. And at a time when the skills gap is widening, this is crucial.

Precise and consistent, robotic systems transform industries by taking on intricate tasks that require dexterity as well as strength. You’ll discover that harnessing this power can yield significant performance increases in various manufacturing processes.

Boosting Production Efficiency: How Six Axes Robot Arm Revolutionizes Industry Growth

When we think about heightened efficiency in manufacturing, the six-axis robot arm is undoubtedly a game-changer.

Take for example Standard Bots integratable six-axis robotic arm, RO1. This incredible machine not only reduces waste due to its unrivaled precision but also enhances productivity by operating round the clock without human fatigue setting back the momentum.

Essential Features and Functions of a Six Axis Robot in Modern Plant Automation

An understanding of the specific features that make six-axis robots so powerful aids in appreciating their impact on modern automation. They include:

- Broad Range of Motion: Mimicking human arm movement, six-axis robots can rotate, swivel, and pivot effectively around complex paths.

- Precision: The exactness delivered by these machines is extraordinary – they rarely miss their mark.

- Versatility: Whether it’s welding tasks or delicate assembly operations, there’s hardly any task a well-programmed robot cannot perform.

- Consistency: A six-axis robot performs consistently without fatigue or slowdowns due to human-like energy constraints. This means fewer errors over long production periods.

In unpacking these core elements, you’ll appreciate how six axis robotic arms represent essential next-level tools for larger plant automation strategies.

Case Studies: Success Stories from Companies Leveraging Six Axes Robots

Delving into real-world applications can truly illustrate the transformative power of six-axis robotic arms. Two compelling examples spring to mind:

- Tesla: Known for its forward-thinking approaches, Tesla has significantly boosted production efficiency through automation. The integration of robots into their assembly lines facilitates around-the-clock productivity, dramatically improving output quality and allowing them to avert bankruptcy.

- Rolex: Precision is crucial in watchmaking and Rolex understands this well. It utilizes robot arms for assembling and testing intricate watch components accurately, ensuring each piece measurably meets high-quality standards.

These success stories effectively demonstrate how advanced robotics can launch your business onto a new trajectory towards rapid growth and prosperity.

Optimizing Your Automaton Strategy with a 6-Axis Robotic Solution

If you are intrigued about the potential represented by the latest robotics, it’s worth looking into the specifics of how to fine-tune your operational processes with their help. Considerations for this strategic planning include:

- Identifying tasks that could benefit from automation.

- Understanding the capabilities of your chosen robotic arm to ensure optimal utilization.

- Implementing phased integration to help staff adjust smoothly.

Your own approach must be bespoke, but these principles can be applied to any plan for adopting advanced robotics.

Future Perspectives: Predictions for the Evolving Role of the 6-Axis Robotic Arms

As we round off our exploration, it’s clear that the role of six-axis robots in manufacturing is poised to expand significantly.

Predicted advancements point toward enhanced capabilities, with more intricate tasks tackled with precision and ease, resulting in profound impacts on industry productivity and competitiveness.

More than just a trend, these robotic aids represent an inexorable pathway towards ultra-efficient production lines, ensuring businesses can thrive amidst ever-intensifying industrial demands.