CNC stands for computer numeric control and ever since its inception, it has remained on top as the most reliable and accurate form of automated manufacturing technique available. Of course, the subtractive method has gone through multiple stages of evolution since then, fine-tuning it into the perfect manufacturing automation technique that we see today.

Taking a brief look through the multiple industries which benefit from products made with CNC machines should help us understand the kind of importance it holds in the market today.

Woodwork with CNC Machining

CNC machines come in different types and versions because each of them is meant for a specific kind of manufacturing. The woodwork industry and furniture businesses generally use a CNC wood router machine for their needs. Some of the many products which the wood router can produce are as follows:

- Doors

- Window frames

- Desks

- Cabinets

- Tables

- Chairs

- Wooden plates

These same products can be manufactured with the same wood router CNC machine, even if the material used in any of the following:

- Glass

- PVC

- PCB

- MDF

- Acrylic

- Plastic

- Soft metals such as brass, bronze or copper

Addition of a Rotary for Cylindrical Processes

On adding the rotary fixture to CNC metal router machine, it can then be instructed to manufacture cylindrical automotive parts such as:

- The parts necessary for fuel injection

- Shafts for motors

- Camshafts for small motors

- Transmission gears

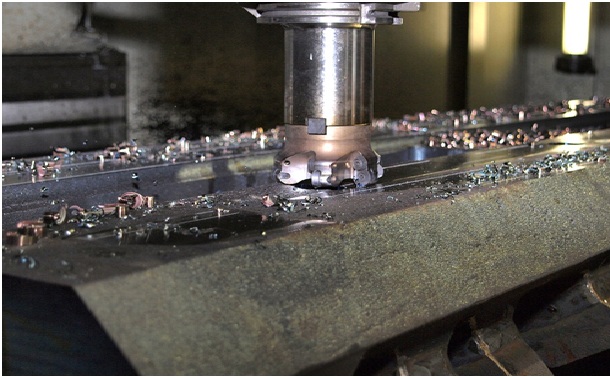

CNC Metal Molding Machine: Ideal for the Automotive Industry

As the name suggests, it’s perfect for molding metals, and we are not just talking about soft metals like brass or copper either. From stainless steel and steel alloys to titanium and even chrome-iron – all can be milled, drilled, and engraved by a CNC molding machine with the aid of a moving table.

However, due to the level of expertise and the high-quality equipment that heavy metal casting and molding requires, it is advised to only trust qualified and experienced contract manufacturers for such high levels of CNC machining services. They should be able to help the customers from designing and prototyping, to mass-scale manufacturing with a comprehensive set of services.

Stones and CNC Machining: It’s Possible

Natural stones can be some of the hardest or the most brittle materials to work with, but a modern CNC stone router can effectively engrave and even cut stones with precision. A heavy machine bed becomes necessary of course, and a plasma or laser head will need to be used for precision, especially while engraving. The most ideal stones that CNC machining can work with without too much of a problem are:

- Limestone

- Soapstone

- Softer marble variants

However, granite and CNC are not ideal for each other, especially in the absence of industrial water cooling.

CNC machining is now also becoming a supportive manufacturing technique in industries where robotics plays a bigger role. AI-powered robots with CNC machines implanted on them can achieve some amazing tasks that neither of the two could, without the help of the other.