It is very essential to ensure the performance and durability of Automation Machine Tools when it comes to keeping them well maintained. Be it routine check-up, maintenance, or particular attachments, keeping machinery tools up-to-date is the major thing to consider. Machines can encounter a problem at any time and due to this anything can happen if they are not maintained precisely and checked correctly. Heavy losses might also occur in businesses. It is well known that CNC machines and machine tools are the backbones of the manufacturing sector as they play a key role in building other machines for all industries. And therefore, ensuring or checking the smooth functioning of such machines is not only important for them but also to the manufacturing sector as a whole.

On the other hand, good quality automation machine tools can be heavy instruments but at the same time, they work for a long time. Here are 6 ways to prolong the life of automation machine tools:

1) Check the lubrication of machine tools

The foremost thing to keep in mind is to check the lubrication of machine tools. The levels of lubrication need to be inspected on a regular basis. You can protect lubrication tools motors easily by ensuring that the equipment is lubricated properly over an extended period. Protecting their motors include oiling, greasing of their moving parts. In order to make your machine tools work without any breakdowns, always have the right amount of oil or use other lubricants.

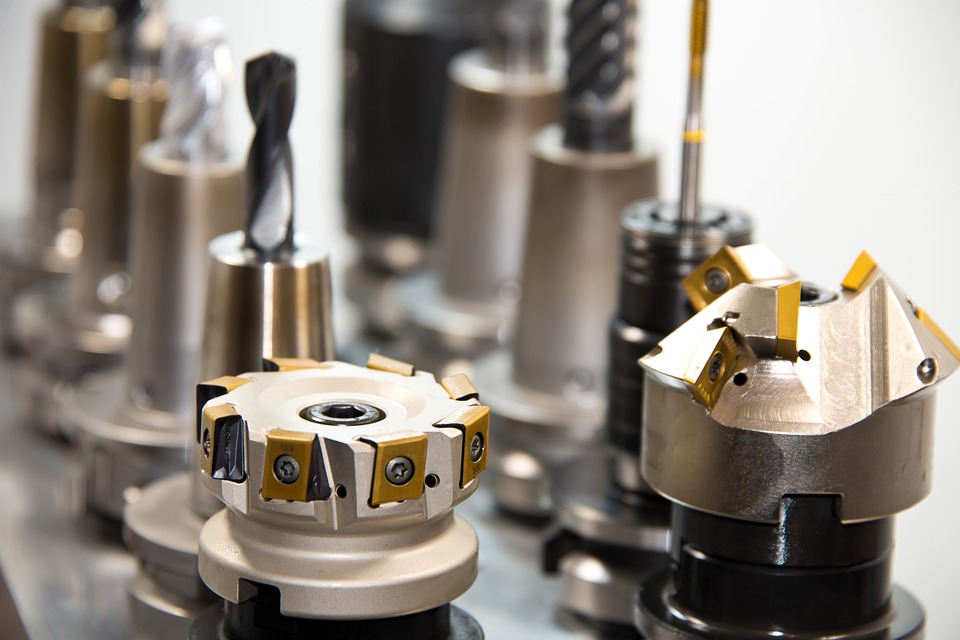

2) Sharpen Key Parts

You need to make sure that the parts maintain their sharpness if you are using machine tools that have components built for slicing, cutting, sharpening or chopping. Check whether the parts are in proper condition or not. And also ensure those equipments used for cutting are sharpened properly.

3) Verify alignment specifications

Another way to maintain automation machine tools properly includes verification of alignment specifications. Component misalignment may adversely affect the machine’s performance. Perform few test jobs to check whether your machine tools are aligned properly or not.

4) Scrutinize the cleanliness

Make sure that machine tools are cleaned regularly either daily or weekly. And also check that they are running at optimum capacity. When machines collect a lot of grunge or start rusting, long-term problems may occur.

5) Parts & Equipments must be checked

It is vital to have routine maintenance checks on all of the accessories and parts. Make sure that all the machine tools, accessories are handled with care and stored safely. Keepchecklistt and carefully maintain all the parts & equipments to enhance maintenance performances.

6) Set machine to correct power mode

Always check the working mode of machines and set them to correct power mode as most machine tools are programmed with multiple power modes.

You can easily prolong the life of your automation machine tools and save yourself from machine breakdowns and unpleasant shocks. The best part in this regard is, you have to check all your machine parts regularly and keep them in optimum working condition.